FZU22

FZU22

Economical and you

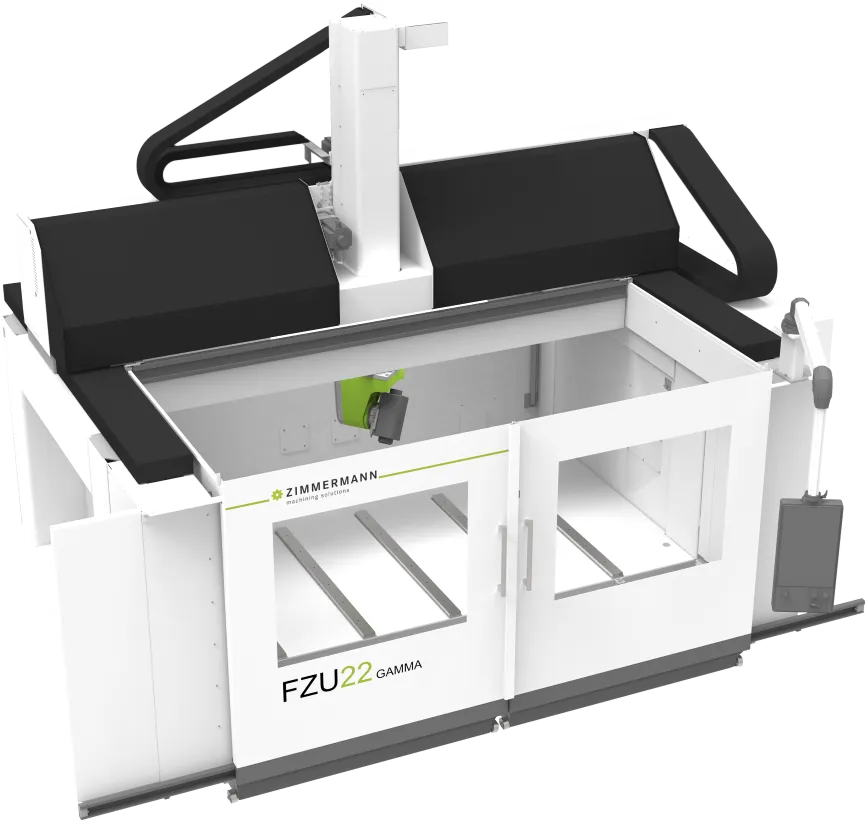

Compact. Universal. Economical.

For the machining of many workpiece shapes and materials, our FZU22 in monoblock structure is ideally suited. Aluminum, plastics and wood are their métier, as is the finishing of CFRP parts (carbon fiber and composites). The top-moving gantry also ensures high precision in the production of models and molded parts. The standard version includes the tool changer for 12 tools and a control of the latest generation (Siemens or Heidenhain). The specially developed 5-axis milling head with 15 kW spindle is also suitable for machining hard-to-reach workpiece locations due to its geometry.

Technical Data

Working ranges

| X-Axis | 1 800/2 500 mm (71"/98") |

| Y-Axis | 3 000/3 500 mm (118"/138") |

| Z-Axis | 1 250 mm (49") |

Clamping bars

| Table load | 500 kg/m² |

| Number of clamping bars | 5 |

| Threaded holes | 30 x M12 |

| Distance between threaded holes | 250 mm (9") |

Drives Linear Axes

| Feed rate X-, Y-Axis | up to 70 m/min (2756 ipm) |

| Feed rate Z-Axis | up to 40 m/min (1574 ipm) |

| Acceleration X-, Y-Axis | max. 3 – 5 m/s² (118-197 in/s²) |

Dimensions

| Required space (without peripherals) | Length | 3 330 – 4 030 mm (130"-159") |

| Width | 6 670 – 7 670 mm 263"-302") | |

| Height | 4 580 mm (180") |

Accuracy

| Standard | in accordance toVDI/DGQ 3441 or ISO 230-2 |

Suitable milling heads

Various.

Available

Stock Machines

Our stock and used machines are available on short notice.