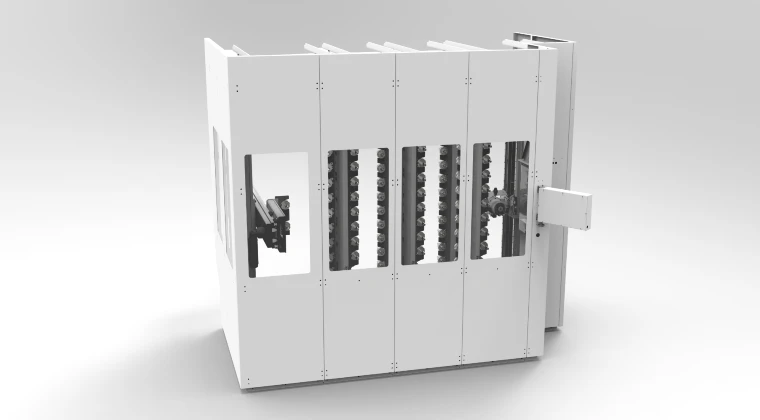

With the FZ – rack magazine ZIM Rack, Zimmermann has developed a compact tool changer for its portal milling machines which can be expanded to accommodate several thousand tools. This modularity allows clients to tailor the system precisely to their production without requiring additional storage space.

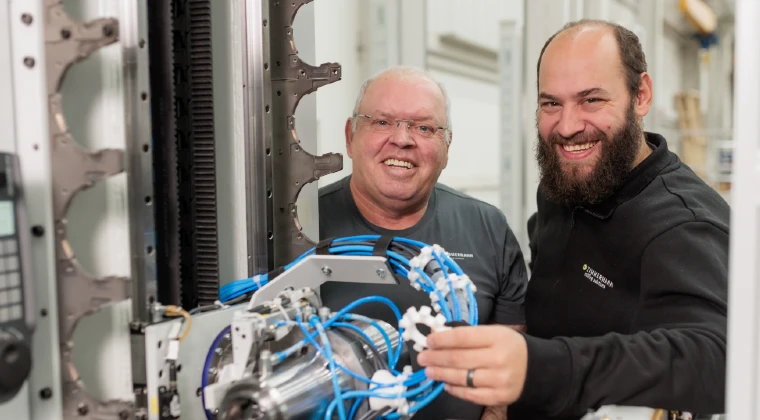

Jonathan Lutz is the mastermind behind the ZIM Rack tool changer and considerably pushed its development forward. The professionally trained and educated mechatronics engineer has been part of the Zimmermann construction team since 6 years, working on milling heads and automation solutions, until he eventually found his calling in the ZIM Rack tool changer.

Jonathan Lutz is the mastermind behind the ZIM Rack tool changer and considerably pushed its development forward. The professionally trained and educated mechatronics engineer has been part of the Zimmermann construction team since 6 years, working on milling heads and automation solutions, until he eventually found his calling in the ZIM Rack tool changer.

Since 29 years Peter Welchner is in charge of the mechanical assembly at Zimmermann and has been travelling the world to install Zimmermann machines. Since the beginning of this year he is part of the internal services team and in charge of installing and assembling the new ZIM Rack tool changer.

What is so special about the ZIM Rack?

Peter: The tool changer is a completely new development by Zimmermann. It is engineered to have a modular design and can be equipped with a wide variety of tools depending on the size. I’ve been involved since the installation of the very first screw, handling assembly and documentation.

Jonathan: Its compact design. A large number of tools fit into a small space. Our goal was to minimize downtime during tool changes and to use the time while the milling machine is operating to prepare and finish other tasks.

What makes this project so exciting for you?

Peter: In the process starting with the engineer, leading to electrical assembly, there are many interfaces and an increased need for coordination. Sometimes we have to get creative when things don’t work out as planned in practice, whether it’s using protective caps from a 3D printer or open cable ducts.

Jonathan: Teamwork is key. In the beginning, you have an idea which then gets developed, takes shape, and is then refined further as a team. I appreciated being able to discuss ideas for refining strategies with my manager, Mr. Wassim, even though this led to some sleepless nights. Peter brings the vision to life and creates the framework, while Felix writes the programs to ensure the timing is just right in the end. Together, we’ve created a product I’m incredibly proud of.

What’s next after the ZIM Rack?

Jonathan: I’m optimistic that with the ZIM Rack, we have a module that can be adapted to many customer requirements with minimal effort. At the same time, there are still many technical possibilities to further optimize the tool changer. The end, if there ever is one, is still a long way off.

CONCLUSION

Tool availability is critical for uninterrupted manufacturing, especially when working with challenging materials. The base version of the ZIM Rack offers 60 slots, expandable in increments of 30. Its functional principle makes it possible to only move the required tools, resulting in minimal wear.

Another additional benefit: The customer receives both the machine and the tool changer from a single source, ensuring faster service in the case of need.

At a glance

- Modular design: The FZ rack magazine ZIM Rack offers space for up to several thousand tools without the need for additional storage space.

- Optimal tool availability: The system allows quick and easy deployment of the required tools, to avoid interruptions during manufacturing.

- Reduced wear: Unlike traditional chain systems, the ZIM Rack moves only the required tools, resulting in reduced wear.